CYLINDER HEAD REBUILD

CYLINDER HEAD REBUILD

elements of our service

Cylinder head disassembly

Crack test

Welding with AWI technology

Surface grinding

Line drilling

Valve seat milling

Valve grinding

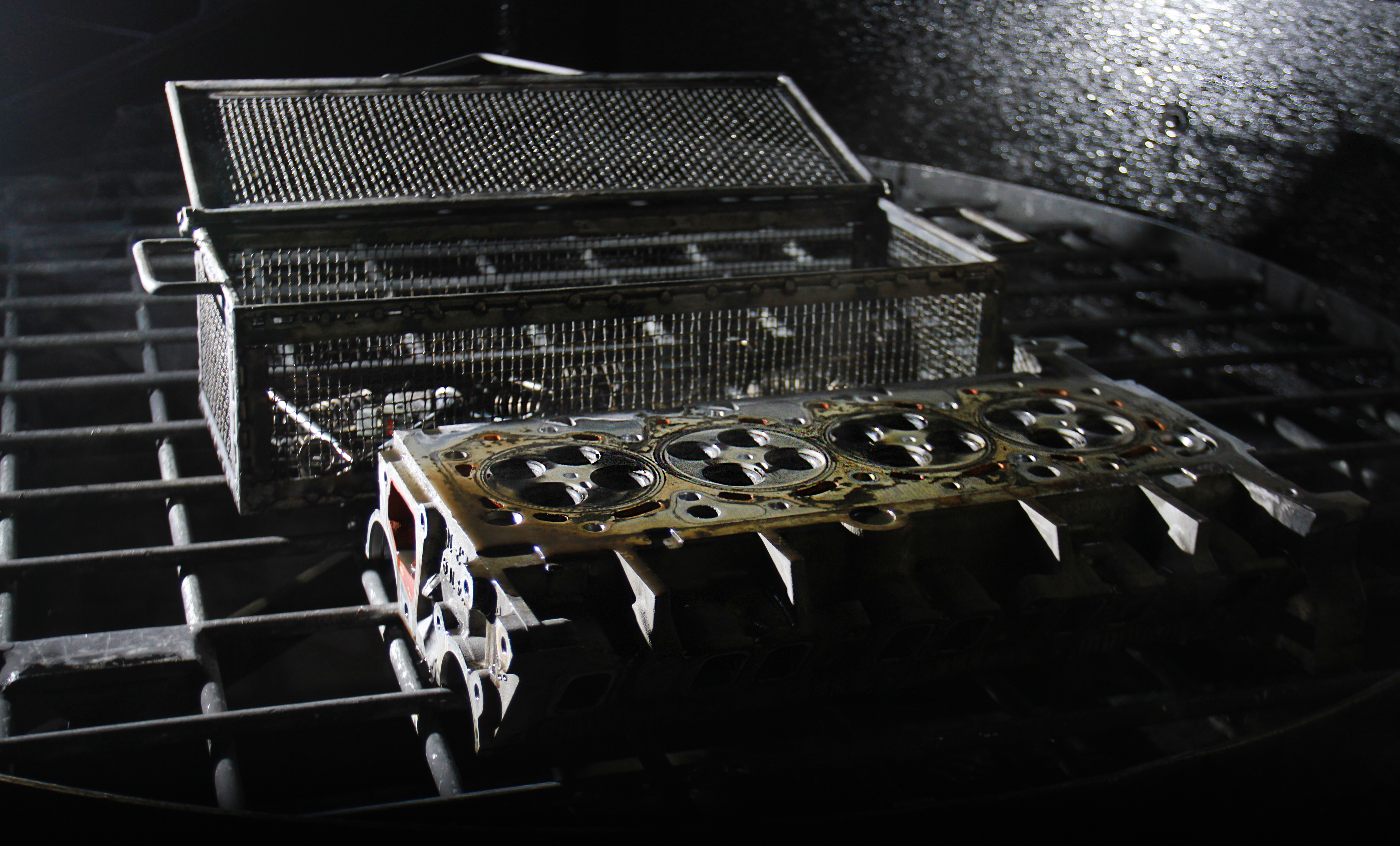

Take a look at the work processes of our workshop!

Cylinder head inspection price

Inspection steps:

The inspection fee in our workshop, depending on the size and condition of the cylinder head, starts from a symbolic net 30,000 HUF compared to the size of the work. Of course, this amount may be higher for commercial vehicles, larger or more complex cylinder heads. The price quote includes the fee for the entire disassembly, washing, pressure testing and inspection process, so if you accept our offer for the renovation, you will no longer have to pay these fees. In the case of individual delivery, the inspection fee will be increased by the cost of delivery.

Contact us with confidence and become our satisfied partner!

Frequently asked questions before cylinder head renovation

DELIVERY OPTIONS

If necessary, our workshop will ensure that the cylinder head to be reconditioned reaches us easily. Our door-to-door delivery service simplifies the commute involved in reconditioning for you. If necessary, we will collect the part requiring reconditioning from your premises and return it to you once the work process is complete.

The primary and most flexible solution for sending parcels is the service of GLS, MPL or Raben. The parcel must be assembled according to the rules applicable to these services. Only clean, oil-free parcels are accepted for delivery, packed in boxes. Larger, palletized goods are delivered by the courier service MPL or Raben.

We undertake the transport of special or heavy cylinder heads. Our workshop has several vehicles reserved for this purpose. If it is not possible to arrange for the parcel to be sent by courier, we will use our own vehicle to pick up the engines in need of renovation. Our fleet has different types of vehicles available for the transport of cylinder heads of different sizes, so large shipments are not an obstacle.

CONTACT

Contact us so that the engine can work again with maximum performance and renewed strength!

WORKSHOP AVAILABILITY

Service manager: tamas.sos@albertmuhely.hu

Central E-mail: info@albertmuhely.hu

Facebook: Facebook